PPSU (Polyphenylsulfone) surgical sterilization trays and cases represent a significant advancement in instrument management and sterile processing workflow. This high-performance polymer has become the material of choice in modern dental and medical facilities, replacing traditional metals and lower-grade plastics due to its unparalleled combination of durability, clarity, and autoclavability. These trays are designed to organize, protect, sterilize, store, and transport delicate surgical and dental instrument sets efficiently and safely.

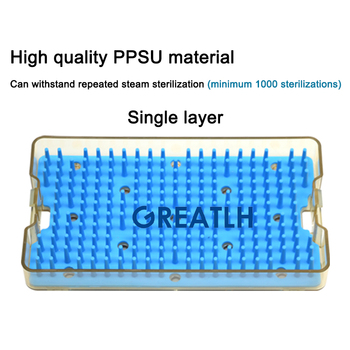

Technical Specifications & Material Science: The trays are precision-molded from medical-grade PPSU, an amorphous thermoplastic known for its exceptional properties. Key characteristics include: Exceptional Thermal Stability – it can withstand thousands of autoclave cycles at 134°C (273°F) and up to 180°C (356°F) for dry heat sterilization without warping, clouding, or losing structural integrity. High Impact and Crack Resistance – it is extremely tough and shatterproof, protecting valuable instruments from damage if dropped. Chemical Resistance – it is resistant to harsh disinfectants, detergents, and sterilization chemicals. Transparency – the natural amber tint allows for visual identification of contents without opening the case. Designs often include perforated or mesh bottoms for optimal steam penetration, secure, positive-latching lids with silicone gaskets to maintain sterility post-processing, and customizable foam or plastic inserts to hold specific instruments securely in place, preventing metal-on-metal contact.

Industry Standards & Compliance: PPSU is compliant with ISO 10993 for biocompatibility and is approved for repeated sterilization per AAMI/ANSI ST79 standards. Manufacturing occurs in ISO 13485 certified facilities. The material meets FDA CFR Title 21 and EU MDR requirements for medical device components.

Application Scenarios: Essential in Central Sterile Supply Departments (CSSD), hospital operating rooms, oral surgery centers, and large dental clinics. Used for sets of implantology instruments, periodontal surgery kits, osteotomy sets, and specialized diagnostic tools. They are equally valuable for mobile dental services requiring secure transport of sterile instruments.

Usage Guidelines: Load cleaned, dry instruments into the tray’s designated slots. Close and latch the lid. The entire sealed case can be processed through a washer-disinfector, ultrasonic cleaner, and autoclave. Post-sterilization, the case serves as a sterile storage container until opened at the point of use. The trays are cleaned alongside instruments in automated washers.

Market Value Proposition: PPSU trays offer a superior return on investment (ROI) compared to stainless steel (lighter, quieter, non-denting) or polycarbonate (which degrades with repeated autoclaving). They dramatically reduce instrument damage and loss, streamline workflow by keeping sets together, and provide auditable evidence of proper sterilization and handling. For suppliers, they represent a high-value, capital equipment sale that builds long-term partnerships with clinics focused on premium instrument care and efficiency.