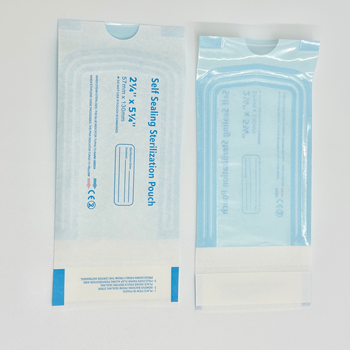

OEM Medical Disposable Self-Sealing Sterilization Pouches are the industry-standard packaging for sterilizing individual instruments or small sets. They combine a transparent plastic front with a porous paper back, creating a package that allows for sterilization, storage, and aseptic presentation.

Technical Specifications & Material Science: The pouch is a laminate: one side is a clear, medical-grade plastic film (often polypropylene or polyester) that is impermeable to microorganisms and allows visual identification of contents. The other side is a sterilization-grade porous paper (like Tyvek® or medical-grade paper) that allows the penetration of steam, ethylene oxide, or hydrogen peroxide plasma during sterilization. The key feature is the self-sealing adhesive strip along the open end, which requires no heat sealer—just pressure to create a secure, tamper-evident closure. Internal process indicators (chemical indicators that change color upon exposure to sterilization conditions) are standard. Pouches come in various sizes and may have date/contents labeling areas.

Industry Standards & Compliance: Must comply with ISO 11607-1 & -2 for packaging for terminally sterilized medical devices and EN 868 series. The paper must meet specific pore size and strength requirements.

Application Scenarios: Used in dental clinics, hospitals, and clinics to package anything from a single dental mirror or forceps to a set of surgical elevators before autoclaving. The sealed pouch maintains sterility until opened at the point of use.

Usage Guidelines: Place the clean, dry instrument inside the pouch, ensuring it does not puncture the material. Remove the protective liner from the adhesive strip, fold over, and press firmly to seal. Write the date and contents on the provided area. Place in the autoclave with the paper side facing the direction of steam flow. After sterilization, the package is stored in a clean, dry area. The seal is broken only when the instrument is needed.

Market Value Proposition: For distributors, sterilization pouches are a non-negotiable, high-turnover consumable with consistent, predictable demand from every clinical facility. Offering OEM (private label) services allows you to put your brand or a clinic’s brand on this essential item, increasing loyalty and brand visibility. The self-sealing feature adds convenience, making them preferable to pouches requiring a heat sealer.